Looking for Phenix Scheduling Software?

Phenix is now QAD Advanced Scheduling! As the original founders of Phenix, Zinata remains committed to delivering top-tier scheduling solutions. As a trusted QAD reseller, implementation partner, and referral partner, we continue to provide the same excellence you’ve come to expect.

Advanced production scheduling that lets you get the most out of your manufacturing assets.

Boost performance by optimizing changeovers and inventory to align production with cash, cost, and service goals. Get back your most valuable asset — time.

Cloud-based production scheduling

Digital transformation is happening across supply chains around the world to keep up with today’s challenges. Don’t let the factory be your last digital frontier.

Manufacturing must be responsive, agile, and predictable for supply chains to be fully resilient. Using a cloud-based advanced production scheduling platform that’s easy to deploy and easy to use, customers are transforming their production scheduling, removing waste, responding to disruptions and getting the most out of their supply chain investments.

Shop talk in the boardroom

Embed executive decisions in your schedules – Shop floor performance gets the boardroom’s attention.

Manage Change

Respond to disruptions in time to make a difference

Enhance Service

Reduce Cost

Spend less on fixing issues caused by poor scheduling and unexpected change

Save Time

Get time back for more productive activities rather than working overtime

Increase Cash

Maximize your inventory and capital investments

Embrace Sustainability

Reduce your carbon footprint by right-sizing inventories and eliminating waste

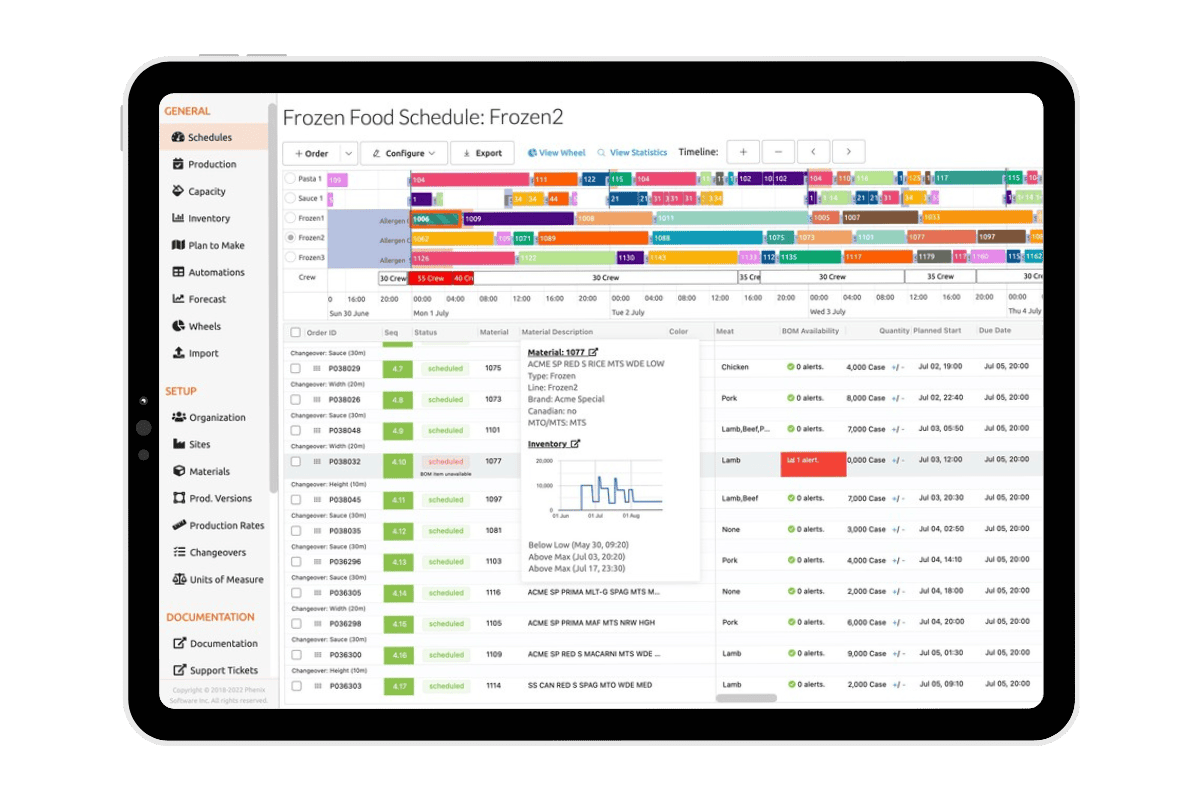

01. Advanced Production Scheduling

Schedule your plants with confidence

Optimize production efficiency by easily deciding what products to make on each line and sequencing them to minimize changeovers, while balancing working capital, service, cost, and sustainability objectives.

Customers see upwards of 50% reduction in the number of changeovers, changeover time, and a 5-30% increase in throughput rates.

Schedule so plants consistently meet business goals under normal and disrupted conditions and deliver optimal manufacturing performance.

Align plans with the rest of the business

Make it easy to schedule

Configure changeover rules

Minimize changeovers

Respond to capacity challenges

Manage resources and raw materials

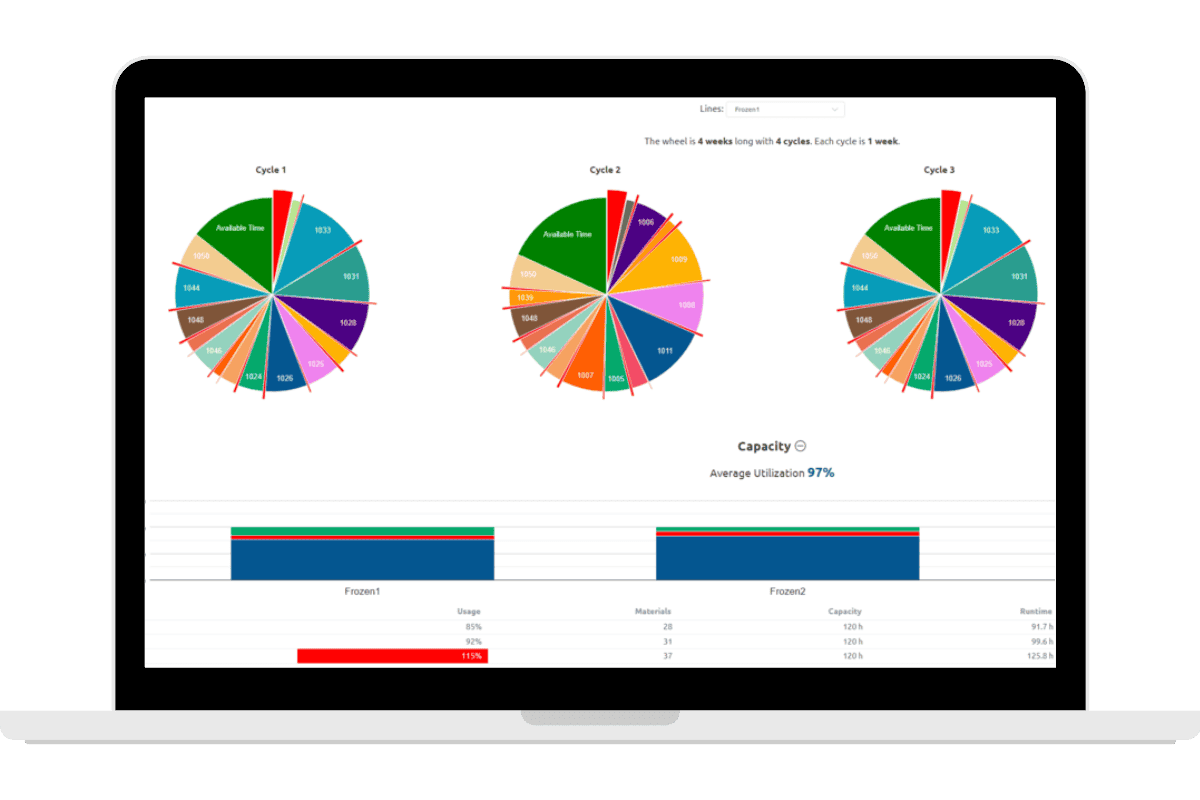

02. Product Wheel Design

Predictable scheduling for an unpredictable supply chain

Product Wheel principles bring predictability and the economies of repetition to your scheduling. Production will fall into regular, repeating cycles, extending this stability throughout the supply chain.

This gives you the ability to make confident decisions when managing rush orders, equipment failures or resource issues.

Leverage Aligned Product Wheels™

Automate scheduling

Quickly analyze advanced production scheduling options

Schedulers can create new schedules in seconds leveraging Aligned Product Wheel™ capabilities. Easily reschedule and immediately see the time and cost impacts.

Automate the most common actions

03. Operating Strategy Design

Bring the boardroom to the shopfloor

Operating Strategy Design unites the boardroom with the shop floor by enabling you to synchronize cash, cost and service goals with production strategies. Evaluate trade-offs with business goals to engineer the best production designs that maximize results.

The balance and trade-offs can be different for different products and families in different regions or for different time periods in seasonal businesses.

Optimize inventory levels

Run simulations to determine optimal operating strategy

Optimize cycle times

Instant impact with the power of innovative scheduling

Changeovers and incorrect inventory levels waste significant time and money, and affect customer service. Advanced production scheduling enables you to minimize waste and align production, ensuring manufacturing is not the weak link in building a resilient supply chain.